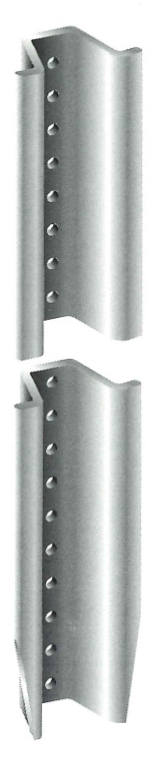

We have been making U Channel Sign Posts in the middle of Steel Country since 1901. Our U Channel Sign Posts are made with some of the most durable stuff known to man. Railroad steel was made to carry the load of freight trains. If it can hold up a train, it can hold up your signage.

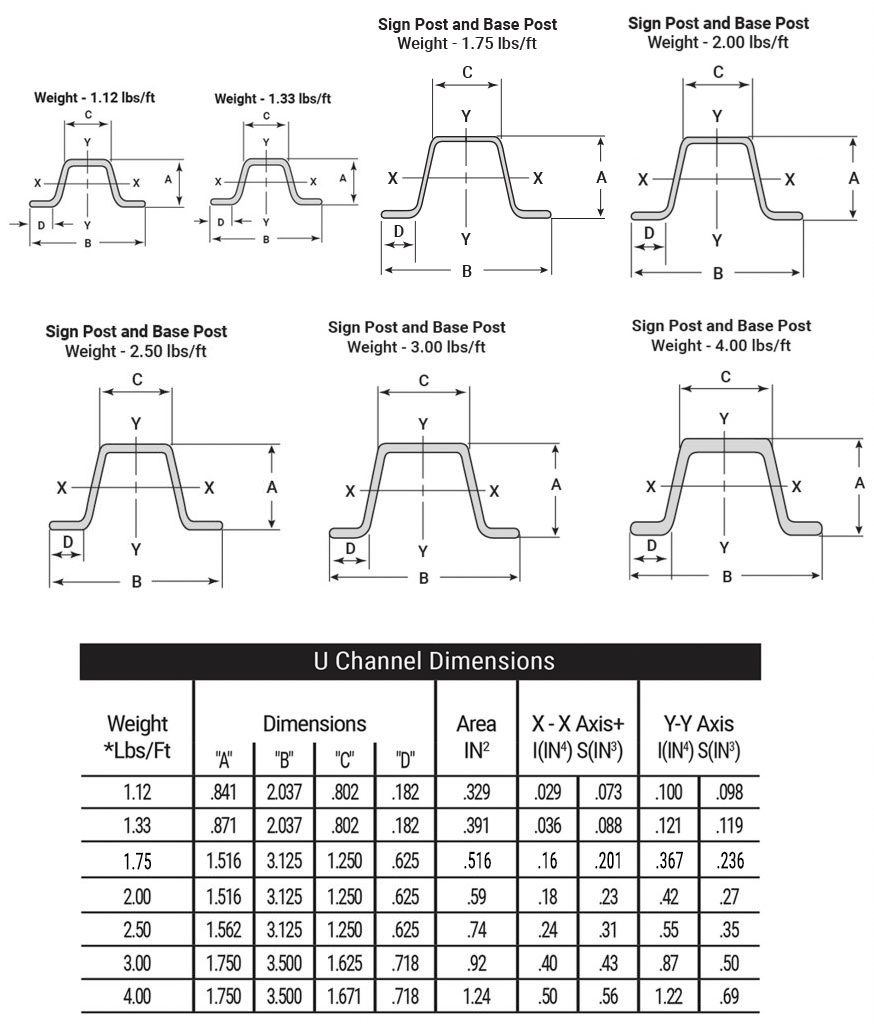

Lengths: Available in 6ft, 7ft, 8ft, 10ft, 11ft, and 12ft lengths. Special lengths also available.

Material: Posts are produced from standard “T” rails weighing 91 lbs/yd or more according to ASTM A499-15, Grade 60.

Punching: .375″ diameter holes on 1.0″ centers, with the first hole 1.0″ from the top.

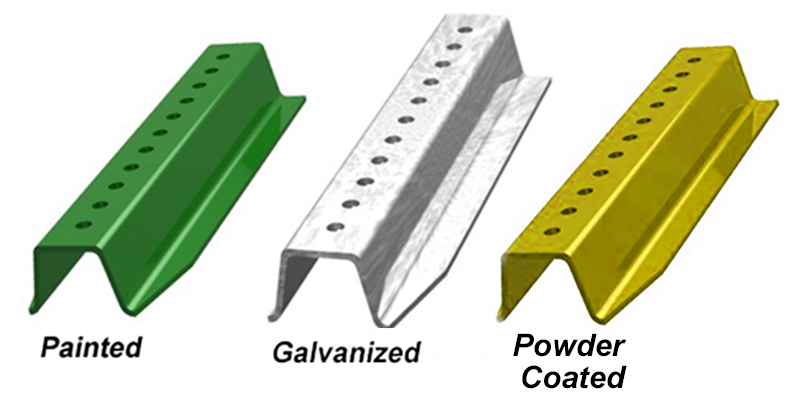

Franklin Industries U Channel Sign Posts are manufactured from high quality, high tensile rail steel and finished with a protective coating of weather resistant baked enamel paint, or galvanized by hot dipping per ASTM A123. They are designed to provide an attractive appearance and years of maintenance-free service. Special colors and finishes can be supplied for special applications.

With Franklin Sign Posts’ great strength and rigidity, you can support the same load with a lighter weight post. And with four different sign post weights and two delineator weights available, you can select the exact post to meet each requirement, buying only the steel needed to do the job. One person can install or replace a complete post and sign assembly in minutes. No digging, drilling or concrete to mix.

NCHRP Report 350 Compliant

FHWA has accepted Franklin Industries sign posts in single and multiple post installations for all Federal-aid routes and projects.

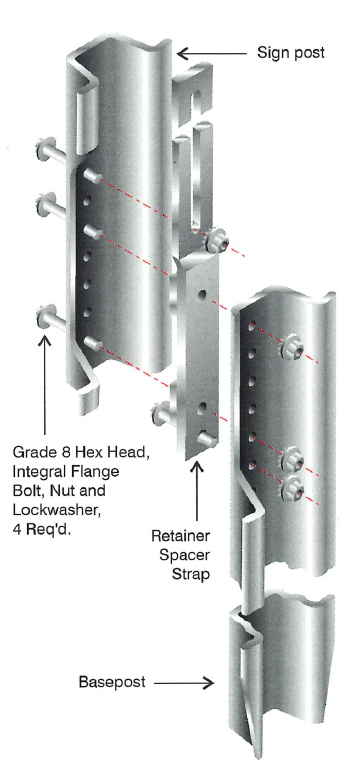

Eze-Erect sign posts’ design permits quick and easy installations from ground level with simple tools. The base posts are readily driven into hard soils, even asphalt. The sign post is then attached with the sign already in place. Crews are quickly trained and most installations take only minutes.

Connection Strength

Eze-Erect sign posts’ connection develops the full design strength of the sign post; there is no compromise in sign supporting capability.

Full Versatility

A complete range of warning, regulatory and guide signs can be supported, from small signs on single posts to very large signs or sign clusters on multiple posts. Eze-Erect sign posts also work well for construction and temporary signing. Whatever your highway message, Eze-Erect sign posts can hold it reliably.

Low Labor Costs/High Salvage Value

When impacted, base posts, sign posts and sign panels are often reusable. Even if damaged, sign posts can often be cut into base posts. And more importantly, because of the breakaway action, expensive sign panels, the major cost component of a sign installation are more likely to be reusable.

Widely Accepted

Hundreds of thousands of Eze-Erect sign posts are in use throughout the country. Try this proven system in your area and see how Eze-Erect sign posts can save you money.

Eze-Erect Specs

Retainer-Spacer Strap: 17.125” long X 1.00″ wide x.375″ thick with .375″ offset. The strap is galvanized to ASTM A123

Bolts: Hex head, integral flanged lock nut or standard Grade 8 hex head bolt and lockwasher.

Nuts: 5/16″ – 18 UNC hex head, integral flange conforming to ASTM A563, Grade DH. Lockwashers: 3/8” heavy duty external type.

Bolts, Nuts and Lockwashers are cadmium or zinc plated for corrosion resistance.

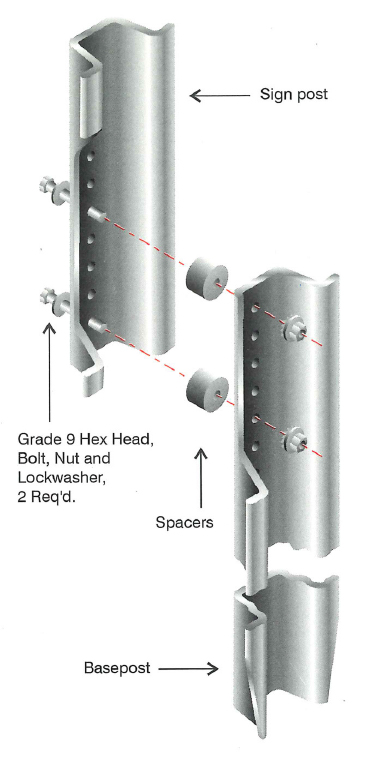

Franklin Industries’ base-bolted sign posts offer many of the advantages of Eze-Erect sign posts at lower cost, except there is no retaining feature. They are an economical alternative when this feature is not required.

Connection Strength

The base-bolted connection develops the full design strength of the sign post; so comparable signs can be supported reliably.

Full Versatility

Base-bolted sign posts will support any type of warning, regulatory or guide signs, from small signs on single posts to very large signs or sign clusters on multiple posts. Base-bolted sign posts also work well for construction and temporary signing. Franklin Industries’ base-bolted sign posts can hold your sign dependably, whatever the message.

Low Labor Costs/High Salvage Value

Base posts, sign posts and sign panels are often reusable after impact with an errant vehicle. If damaged, sign posts can often be cut into base posts. But more importantly, because of the breakaway action, expensive sign panels, the major cost component of a sign installation, can most likely be reused.

Base-Bolted Specs

Spacers: 1.0″ diameter x .625″ thick with .438″ hole with an elastomer insert. The spacers are zinc plated for corrosion resistance.

Bolts: Hex head, fully threaded Grade 9, 5/16″ – 18 UNC x 2.25″

Washers: 5/16″ Grade 8 Nuts: Hex head, integral flanged lock nut or standard Grade 8 hex head bolt and lockwasher.

Bolts, Nuts and Washers are cadmium or zinc plated for corrosion resistance.

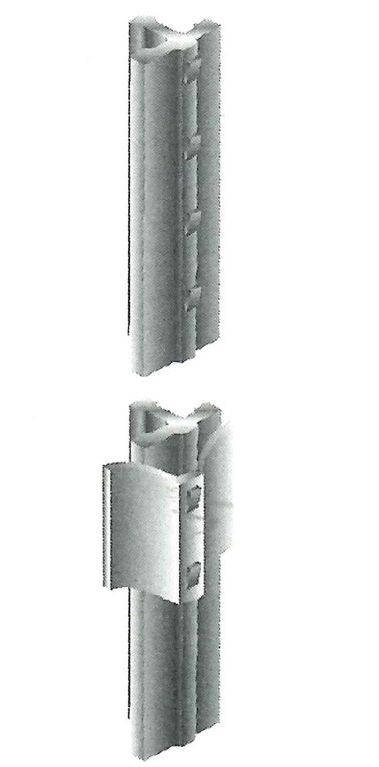

Right-of-Way and Silt Fence Posts

Franklin Studded ‘T’ Posts are designed for easy installation and trouble free service for right of way and silt fencing. Heavy anchor plates protect against natural “lifting” and vandalism. They are available in 1.25 and 1.33 lbs/ft (ASTM A702) and are either painted or galvanized.

Drive Caps For Safe Installation

Protect post ends from driving damage. Driving caps are made of cast steel to withstand constant driving. Available in sizes to fit all Franklin Industries Posts.

Delineator – 3.0 lbs ea., for 1.12 to 1.33 lbs/ft posts

Standard – 11 lbs ea., for 2.0 to 4.0 lbs/ft posts

Heavy Duty – 17 lbs ea., for 2.0 to 4.0 lbs/ft posts