T Posts

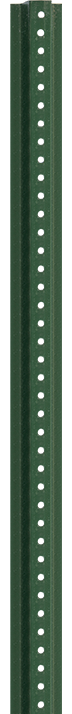

Our T Posts are made from 100% high quality rail steel, built to last. No digging required, T Posts can be installed with a post driver. Choose between unfinished, baked enamel, powder coat, or galvanized finish.

Ideal for

- Wire Fencing

- Wire Mesh Fencing

- Silt Fencing

- Temporary Fencing

- Grape Trellises